At EnduroSat we strongly believe in the endurance of our systems. Our mission is to ensure that each of our platforms will survive the unforgiving Space environment

The platform’s performance is critical throughout the mission, which is why we go above and beyond in our testing process. The rigorous space qualification program covers all aspects of testing. For reliable data, we have invested in cutting-edge labs.

The platform’s performance is critical throughout the mission, which is why we go above and beyond in our testing process. The rigorous space qualification program covers all aspects of testing. For reliable data, we have invested in cutting-edge labs.

Our qualification process has three different segments: Batch Qualification, Satellite Protoflight Qualification, and Radiation Assurance.

Qualification Facilities

EnduroSat performs the qualification test campaign of its modules and platforms in-house and at the Space Qualification Laboratory of the Italian Aerospace Research Centre (CIRA). Radiation testing has been performed at ESTEC’s Cobalt 60 facility, CERN’s GIF++ facility and GAMRAY irradiation facility at TRAD.

EnduroSat’s Qualification program is based on 3 main steps:

- Initial Qualification:

All EnduroSat components and standard platform configurations undergo qualification based on tailored ESA ECSS-E-ST-10-03 methodology and environmental levels defined as per NASA GEVS: GSFC-STD-7000A for random vibrations, shock and thermal vacuum testing at qualification levels

- Batch Qualification:

To ensure the highest standard of craftmanship, up to 5% of each batch of produced components undergoes as a minimum random vibrations and thermal vacuum testing per NASA GEVS: GSFC-STD-7000A at qualification levels

- Protoflight Qualification:

After a final Assembly, Integration and Testing (AIT) campaign, EnduroSat satellites undergo protoflight-level qualification per the relevant launcher documentation. Campaigns conducted so far include, but are not limited to the requirements of SpaceX Falcon 9 RPUG, Orbital ATK Antares rocket, ISAR Aerospace Spectrum Payload User Guide

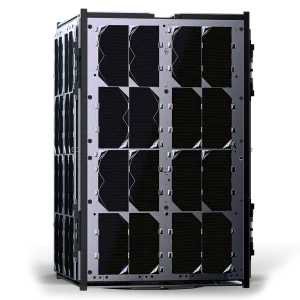

In-house equipment distributed in 500 m2 of cleanroom facilities and cutting edge laboratories, including 200 m2 ISO 7 14644 Class facility.

| Equipment | Specifics | Parameters |

| TVAC Chamber | TVAC Chamber ACS HVT

1100 |

Temperature range: -70° C to +120° C

Vacuum limit: 10-7 mbar Useful capacity: 940 liters |

| Climatic and thermostatic chamber | ASC DI 200 | Temperature range: -40° C to +180° C

RH: 10 – 95% Useful capacity: 206 liters |

| ADCS Test Bench and Mass Properties tool | Custom, developed by Tensor Tech | 3-axis Helmholtz cage

Air bearing platform AM0 Solar simulator Centre of Mass (CoM) and Moment of Inertia (MoI) measurement for up to 16U platforms |

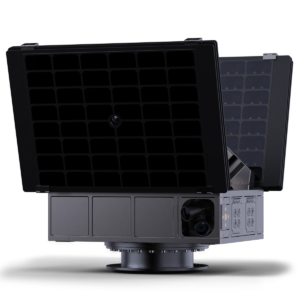

| Anechoic Chamber (from Q2 2024) | ETS-Lindgren AMS-8500 Antenna Measurement System | Frequency range from 1 GHz to 40 GHz when the satellite is in transmission or receiving mode |

| Test and measurement equipment | Multimeters

Electronic Power Supplies Electronic Loads Oscilloscopes Spectrum Analyzers Weight Scale Reference modems and SDRs |

In-house capacity for Vector and Spectrum analysis measurements up to 110 GHz |

Batch Qualification

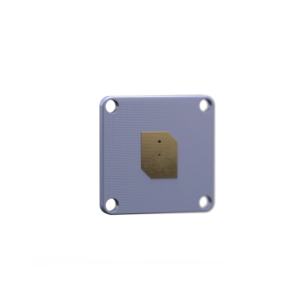

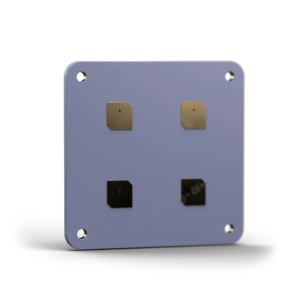

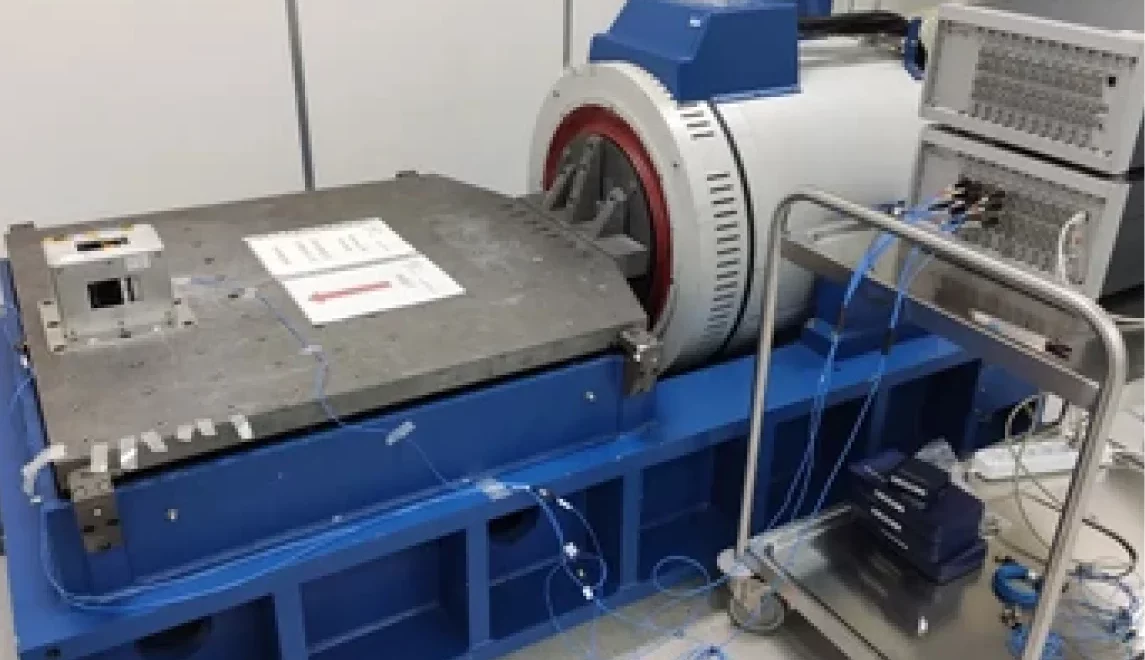

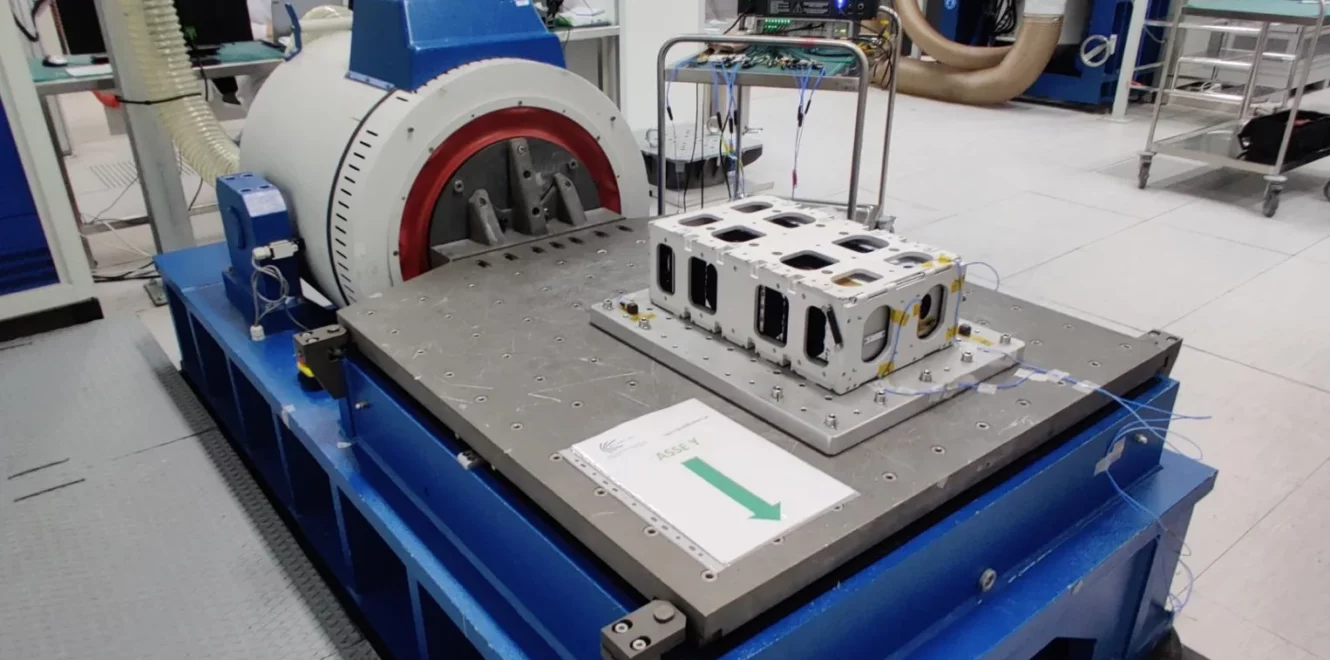

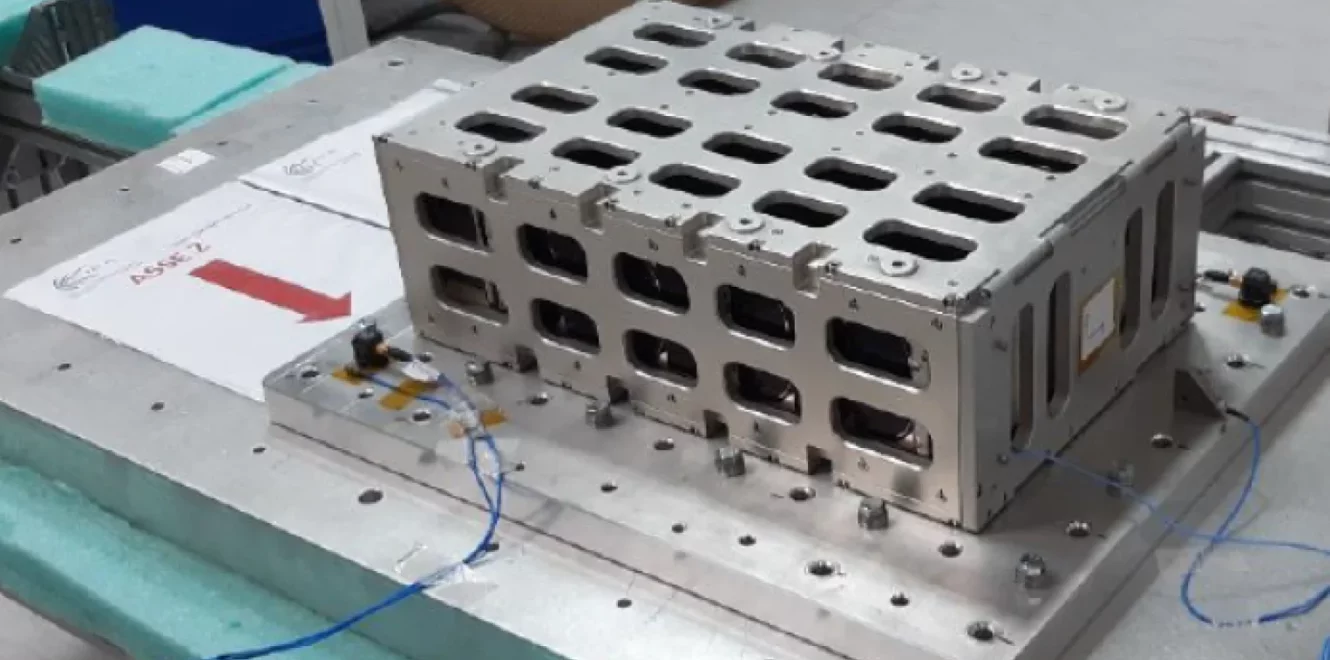

EnduroSat is committed to ensuring that each satellite component is capable of surviving the severe launch and Space environments. Therefore, a representative number of devices from each production batch (typically 5%) undergo a series of tests before the rest of the batch components are released for customer delivery. For batch qualification, the standard tests performed are the resonance search (before and after the random vibrational tests), random vibrations, and the combined thermal vacuum and thermal cycle. Shock test is not performed on each batch, but each new device undergoes such test during its initial qualification.

After all tests qualification tests are completed, a functional verification is conducted to ensure that the components from the given batch are operating as expected.

Resonance Search

The resonance search is performed for each of the 3 axes, before and after any remaining vibrational tests are conducted, in order to detect any dynamic response variation or structural fault, highlighted by frequency peaks’ changing or amplitude response modifications that could arise from applied test loads. Sine sweeps are performed by using a shaker and accelerometers are used to measure the acceleration in each of the three orthogonal axes.

The satellite components must undergo a sine sweep, for resonance search, with the following characteristics:

| Level | Duration | Number of applications | |

| Frequency [Hz]

5 20 50 700 800 925 |

Level [g] 0.2 |

2 oct/min | 1 on each of 3 orthogonal axes before the random vibration test is conducted and 1 on each of 3 orthogonal axes after the random vibration test as a success criteria |

Random Vibrations

The random vibrations test is performed by using calibrated shaker. The test is conducted at GEVS qualification levels for 2 minutes in each of 3 orthogonal axes of the components following the table below:

| Frequency [Hz] | PSD [g2 /Hz] |

| 20 | 0.026 |

| 50 | 0.16 |

| 800 | 0.16 |

| 2000 | 0.026 |

| GRMS | 14.1 g |

Combined Thermal Vacuum and Thermal Cycle

The components are subjected to a simulated Space environment to test their ability to operate in extreme thermal and vacuum conditions. The purpose of the thermal vacuum and thermal cycling test is to demonstrate that the system is able to survive, without loss of integrity or functionality, the thermal and pressure conditions experienced in the Space environment.

For the test execution, the integrated temperature sensors of the chamber are used to measure the temperature inside the thermal chamber in order to obtain a measure of the difference between the set temperature and the actual temperature. Moreover, communication cables are installed in order to interface with all devices and gather data from them during operations. For this, the devices are fully operational during the test execution.

The temperature and pressure envelope for the test are based on the GEVS qualification levels, where the upper temperature is reduced only for the battery package of the EPS system for 8 cycles in total:

| Level | Dwell time | Duration |

| -35 to +75 deg C (+65 deg C for components containing batteries)

Pressure: 10-5 hPa or less. Temperature variation rate: |

2 hours at extremes | 8 temperature cycles |

Satellite Protoflight Qualification

During a Space qualification campaign, EnduroSat satellite flight models undergo tests at protoflight levels to demonstrate the integrity of the system. The qualification process is performed following the respective launch provider requirements, following the specifications of the ESA ECSS-E-ST-10-03C and NASA GEVS: GSFC-STD-7000A standards in terms of test execution.

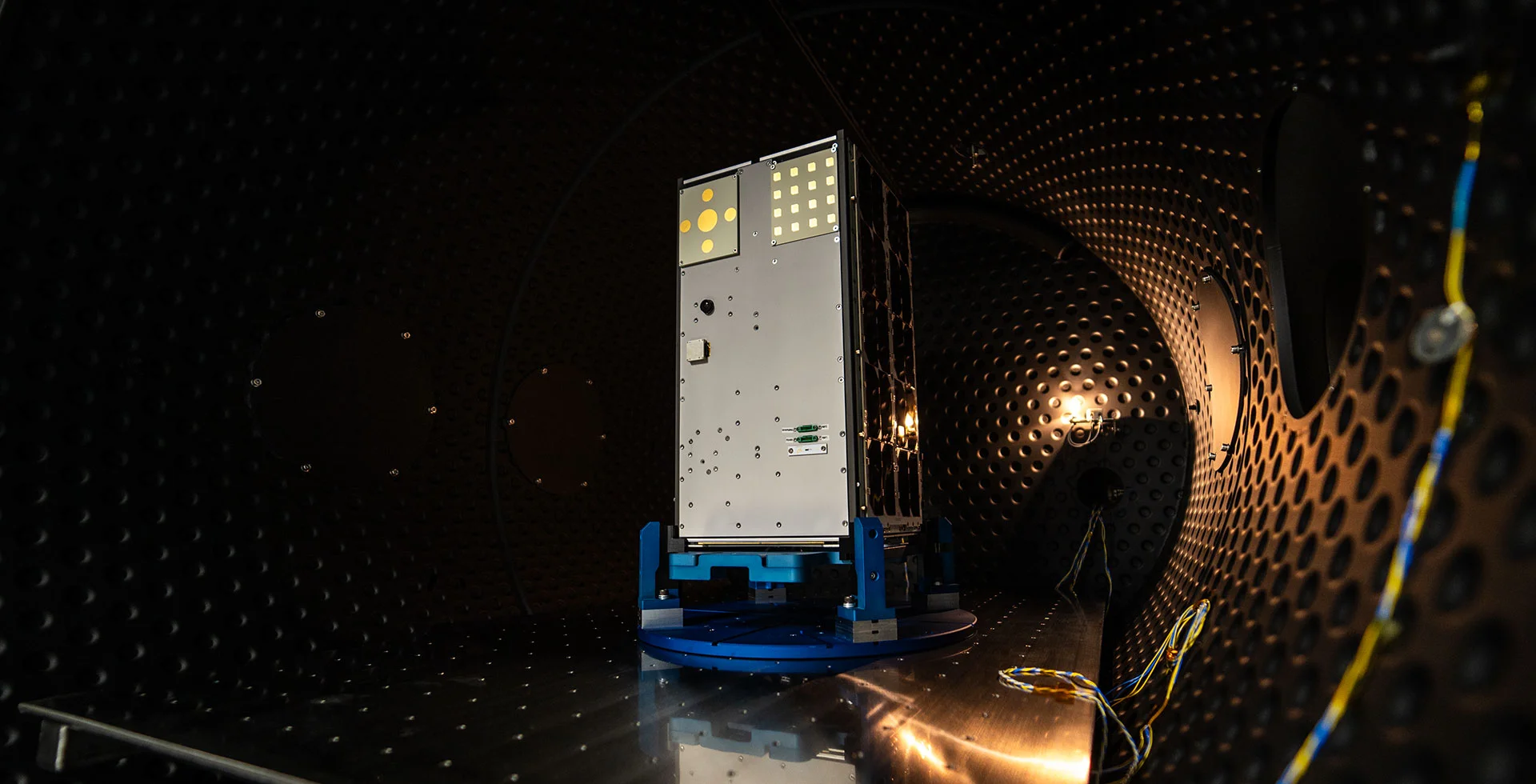

A typical qualification campaign is illustrated in the figure below, where the satellite is subjected to a different set of conditions to replicate the environment that it will experience during launch and in Space. All qualification campaigns are conducted at EnduroSat’s own facilities or at other partner facilities, using calibrated equipment, with the models and calibration status included in the final report delivered. The following figure outlines a typical protoflight qualification campaign.

Functional Test

Before subjecting the satellite to any environmental tests, a functional verification is carried out to ensure that the satellite is operating as expected. These functional tests are mission-specific but always include sending commands to all bus components over the air in order to ensure all harnesses are connected well, as well as full verification of the main functionalities of the bus and its subsystems. The mission-specific aspects of the test are those related to the payload functioning and the specific payload concept of operations.

EnduroSat maintains a set of standard tests for all standard bus functionalities, which are executed in the form of automated scripts with automatic verification of the expected results. Payload-specific testing is performed manually or as part of additional scripts.

In both cases, for a functional test to be considered successful, each of the commands must be performed in sequence and the returned values should match the set of expected test values.

- General visual inspection of the satellite and mechanical fixture to verify that there are no visible cracks or other physical damage

- Verification that fasteners are not loose/have not lost torque.

Physical Properties Determination

In some cases, the physical properties of the satellite are measured at the start of the qualification process. EnduroSat has the necessary equipment to complete the measurement of all key properties for satellites up to 30 kg, including:

- Mass

- Center of Gravity (CoG)

- Moment of Inertia (MoI)

More massive satellites of the ESPA class are measured by using partner facilities.

The precise mass of the satellite is measured in all cases, while the CoG and MoI may be obtained only from the mechanical CAD in some cases.

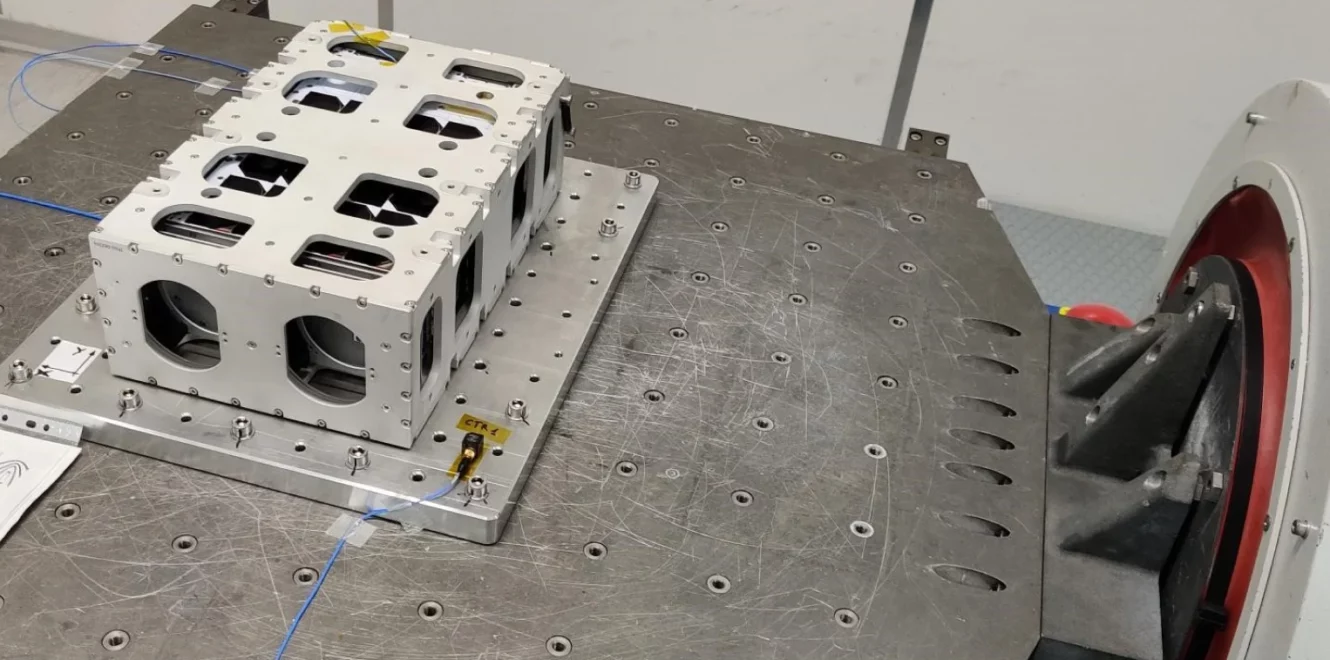

Mechanical Tests

These tests are conducted to verify the structural integrity of the satellite and its ability to withstand the harsh environment during launch and deployment. The objective is to demonstrate that the primary structure and all electronic and mechanical components can withstand the vibrations and the loads experienced in this environment. During the mechanical tests performed, the satellite is enclosed within a test pod and is switched off as in the actual flight.

After the mechanical tests, another functional verification is conducted to ensure that the satellite is still operating as expected.

Resonance Search

The resonance search is performed for each of the 3 axes, before and after the remaining tests are completed, in order to detect any dynamic response variation or structural fault, highlighted by frequency peaks’ changing or amplitude response modifications that could arise from applied test loads. Sine sweeps are performed by using a shaker and accelerometers are used to measure the acceleration in each of the three orthogonal axes.

| Level | Duration | Number of applications | |

| Frequency: [Hz]

5 20 50 700 800 925 2000 |

Level [g] 0.2 |

2 oct/min | 1 on each of 3 orthogonal axes before all other tests are commenced and 1 on each of 3 orthogonal axes after the remaining tests are completed |

Static Load

The static load is achieved through a Sine Burst test based on the levels required by the respective launcher static load factors at protoflight testing.

All EnduroSat CubeSats are qualified as a reference to the SpaceX RPUG static load factors for CubeSats, using an input frequency smaller than 2/3 of the satellite first harmonic.

Random Vibrations

The random vibrations test is achieved through a shaker based on the levels required by the respective launcher static load factors at protoflight.

The table below provides a reference for the protoflight random vibrational tests performed for SpaceX Falcon 9 rideshare missions, conducted for 1 minute in each of 3 orthogonal axes.

| Frequency [Hz] | PSD [g2 /Hz] |

| 20 | 0.02 |

| 50 | 0.03 |

| 700 | 0.03 |

| 800 | 0.06 |

| 925 | 0.06 |

| 2000 | 0.01288 |

| GRMS | 7.877 |

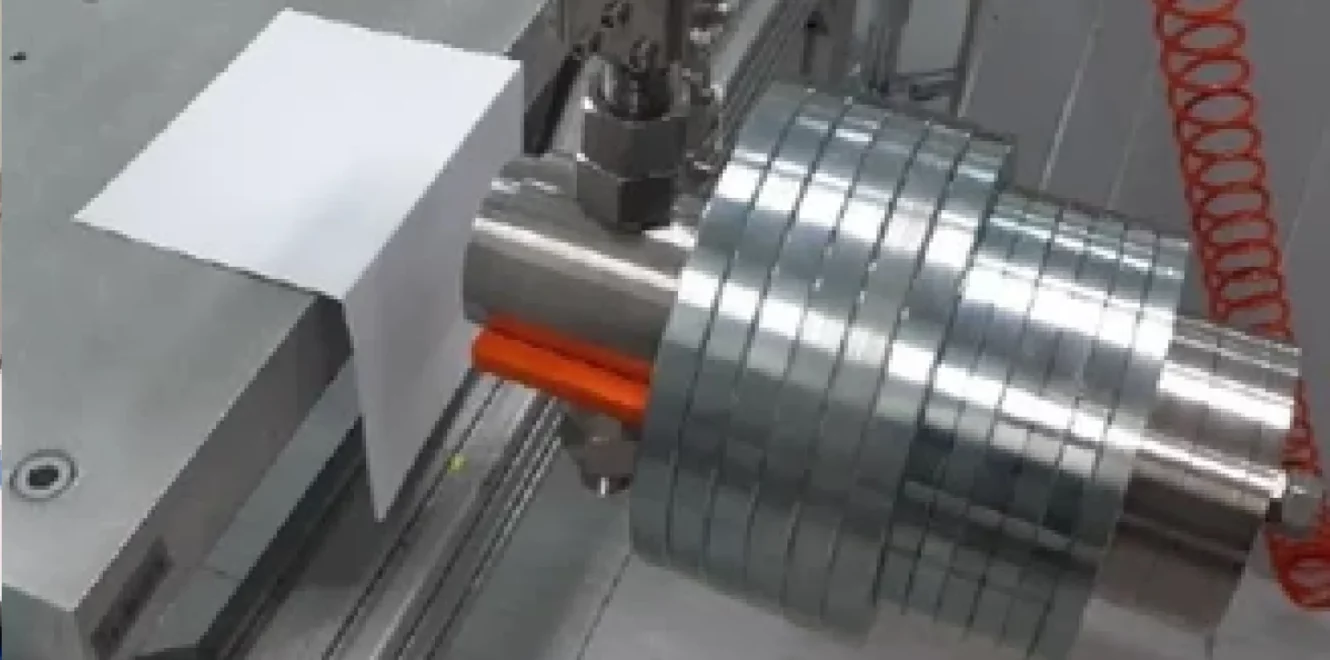

Shock

The shock test is considered advisable by most launch providers and so it is typically performed only at qualification and not for each satellite flight model (FM).

The table below provides a reference for the protoflight shock tests performed for SpaceX Falcon 9 rideshare missions, conducted with 2 repetitions in each of 3 orthogonal axes without considering the payload separation system shock.

| Frequency [Hz] | Shock Response Spectrum (SRS)[g] |

| 100 | 60 |

| 1000 | 2000 |

| 10000 | 2000 |

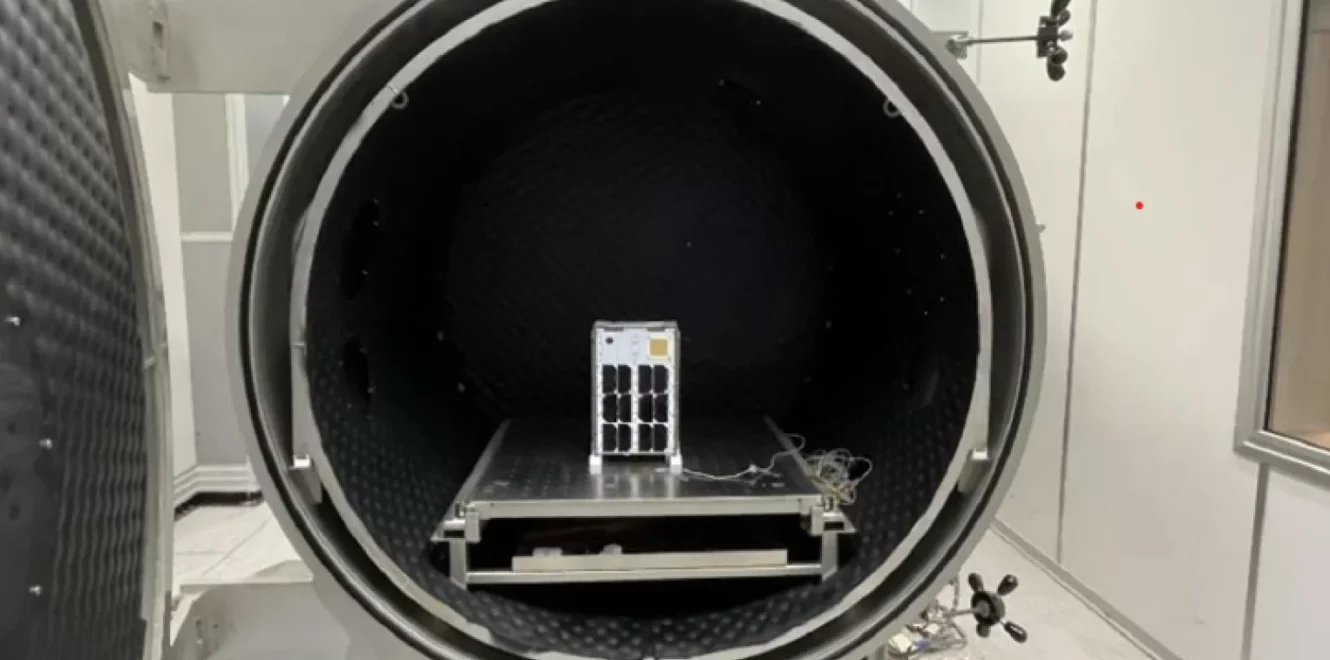

Combined Thermal Vacuum and Thermal Cycle

The satellite is subjected to a simulated Space environment to test its ability to operate in extreme thermal and vacuum conditions. This test is typically not required by launch providers but EnduroSat conducts it as a minimum based on the information provided below in order to ensure the satellite’s fitness for the Space environment.

For the test execution, the integrated temperature sensors of the chamber are used to measure the temperature inside the thermal chamber in order to obtain a measure of the difference between the set temperature and the actual temperature. Moreover, communication cables are installed in order to interface with all devices from the satellite and gather data from them. For that, the satellite must be turned on during the test execution. The temperatures of the satellite components are measured using the integrated sensors inside of each device, while additional temperature sensors are placed on control points on the outside of the integrated spacecraft which are used as a reference for the profile.

The table below provides a reference for the TVAC testing performed for SpaceX Falcon 9 rideshare missions, conducted at 8 cycles in total and taking into account ±5 degC from the acceptance envelope.

| Level | Dwell time | Duration |

| -29 to +66 deg C

Pressure: 10-5 hPa or less. Temperature variation rate: |

2 hours at extremes | 8 temperature cycles |

Functional verification is conducted throughout the entire TVAC test in order to ensure that the satellite is still operating as expected. A final functional verification is conducted outside of the TVAC after all cycles are completed.

Final Functional Verification

This is the final step where the satellite’s functionality is verified to conclude the test outcome. A functional verification is carried out to ensure the satellite is operating as expected in the same way as described in the first part of this page.

After the complete campaign, a visual inspection is further performed to ensure that no external components are damaged in any way and to confirm that no fasteners are loosened or influenced in any way by the vibrations.

Radiation Assurance

EnduroSat has an internal Radiation Assurance strategy to ensure that our systems withstand and operate effectively in the intense radiation environment of Space.

Our radiation hardness assurance approach is based on risk management. For a given project or mission, the orbital parameters are used to carry out simulations of the radiation environment and effects. These simulations use the standard models using existing tools such as the SPENVIS tool. The results allow for a quantification of the radiation levels expected on the mission from each constituent particle species, considering the shielding effects of the components encapsulation.

TID & SEE tests are carried out at the board level based on typical LEO doses. For TID, the boards are tested at 40 krad(Si) unshielded annually, which is equivalent to more than 15 years in LEO environment at board level, given only the individual components encapsulation and without considering the additional effects from geometry and external (solar panel boards) shielding. SEE tests are carried out with 1 MeV protons at board level in order to ensure that the devices are not susceptible to soft errors, while critical EEE components are individually screened for heavy ion test results during the components selection phase where no flight heritage is already available. The first such SEU testing will be performed in 2024.

During annual TID testing, the test is conducted on fully representative engineering models, connected in the same way they are within a satellite but without any external encapsulation/shielding, using a protoboard PCB.

Mission-specific analysis is performed based on specific TID and SEU susceptibility requirements, comparing the simulation fluences for the given orbit with the board test results and the EEE results available from third parties in order to estimate the mean lifetime before failure. A factor of at least two (2x) is taken for all values in order to account for EEE components variation between batches, while typically this factor is 3x for most missions.

Annual TID tests have so far been performed at ESTEC’s Cobalt 60 facility, CERN’s GIF++ facility, and the GAMRAY irradiation facility at TRAD.